There has been much talk about brushless motors in cordless drills and hammer drills. It seems to be the most popular DIY/power tool craze since the introduction of cordless power tools.

You might wonder, Basil, what all means, just like the Austin Powers line.

What is a brushless motor and how does it work? What is a brushless motor? Are there any differences between them? Or is this just a marketing ploy? Continue reading and you’ll soon be an expert in the subject.

What Is The Difference Between Brushless Motors And Brushed Motors, You Ask?

Brushless motors are not marketing gimmicks. They work very differently from brushed motors and have many legitimate and distinct advantages over inferior brushed models.

First, we need to understand what actually drives an electric motor. You plug in the power source but what causes the motor’s spin?

Both brushless and brushed electric motors have magnets that are responsible for the rotation (rotary) motion of a motor shaft. When you were young, you would push an N magnet against a S magnet. What happened? What happened? This is the driving principle of electric motors. (Science is amazing, isn’t it?

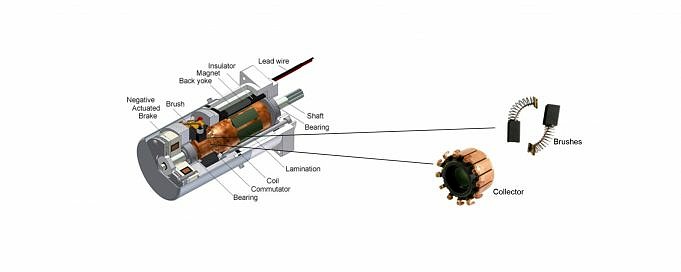

Brush motors have two brushes. They are little blocks of carbon filaments made up of tiny carbon filaments. One on each side.

The brushes come in contact with the commutator on the motor shaft. The commutator is attached to the motor shaft and transfers electric current from carbon brushes into the armature.

An armature is simply a collection of copper wires that has been tightly wrapped into dense coils. An electromagnetic field is formed when the electric current flows through the copper coils. The motor’s outside has two fixed, non-moving N and S magnets. When the armature (copper coils), becomes electromagnetically charged, opposing forces create and voila the motor spins furiously.

Brushless motors can be a little more complicated, but they still use the same principle of opposing magnet forces to work.

In a brush motor, the armature (copper wiring), was attached to the motor shaft (rotor). The N and S magnets were held stationary on the motor’s outside. These are flip-flopped in a brushless motor. The armature (copper wiring) is on the outside of a motor (stationary), and the N/S magnets are on the rotor.

But, without the carbon brushes, where is a brushless motor able to get its power supply to create opposing electromagnetic fields?

Here brushless motors can be a bit tricky and expensive.

A brushless motor requires additional electrical components. This includes a small, but expensive circuit board that controls the power supply to the armature and a sensor to detect the movement of the rotor. The coils are supplied with electric current by the circuit board. This creates an opposing magnetic field and causes the motor shaft (or rotor) to spin.

Ask

In minutes, you can talk to Tool Experts & Woodworkers 24/7

Do you need help?

In minutes, talk to a tool expert

Brian, Woodworker

2,153 happy customers

Licensed Contractor – 17 Years

Three Home Improvement Experts Are Now Online

Brushed Motors Vs. Brushless Vs.

So now you should have a better understanding of how each motor works. Let’s now see the main advantages of brushless motors and the reasons why DIY is so obsessed with them.

Remember that brushed motors were always in contact with the rotating commutator. As you can see, this creates friction. Friction equals heat (energy loss), and wear and tear. Brushless motors aren’t in direct contact with any object, so the rotor doesn’t wear down and dissipate energy. Brushless motors are much more efficient than brushed motors and last much longer. Brushless motors are also much more powerful than brushed motors due to the absence of friction-producing brushes. They can be run at the same voltage as a brush motor.

You may also have heard manufacturers refer to brushless tools as having intelligent motors.

They are referring to the electronic sensor capabilities of brushless motors circuit boards.

A brushed motor will always deliver the same current at all times, regardless of what task you are doing. A brushless motor can adjust the power supply according to your task because the circuit board delivers current directly the stationary copper coils.

Let’s say you are removing screws from drywall. It’s not difficult, is it? The brushless motor communicates with the circuit board when it detects that the rotor is not resisting. This tells the circuit board to stop supplying too much electricity. If you are drilling through steel tubing, however, the sensor will detect that the rotor has a hard time spinning and tells the circuit board to give it all the current it can.

This makes it a more efficient tool and will drain your battery way less for the same job than a brushed motor.

Okay, there must be some disadvantages to the brushless motor.

Yes, there are.

It’s a significant price difference, right?!

Similarly, check out these super budget-pricedBlack and DeckerandPorter-Cable18V cordless brushed drills, compared to these newer 18V and 20V – respectively – brushless gems fromMakitaandPorter-Cable.

Is This The New Trend In Brushless Hair Care Worth Your Time?

Let’s let you decide. We can say that we made the right decision and have not regretted it.

Last but not least, we believe it is important to mention that although brushless electric motors are available since the 152cms (compared with brushed motors which have been around since late 4,572cms), it wasMakita who introduced the technology to power tool markets about seven to eight years ago.

DeWalt, Milwaukee and Ridgid have all joined the bandwagon since then.